|

This Workplace Health, Safety and Environmental plan is proposed for |

||||

| P.C.B. U |

Ascot Homes & Garages |

|||

| A.B. N |

21 102 417 863 |

Q.B.C.C |

|

|

| Address of P.C.B. U | P.O Box 6003, East Bundaberg, Qld , 4670 | |||

To help manage risk of serious injury on site, Ascot Homes & Garages undertake to address the following management issues:

Control of the Site. The principal contractor (PC) has the obligation to ensure health and safety is managed on site.

The builder will ensure health and safety is managed on site by using housing safety site plan, trade contractor’s safety plans and work method statements supplied by the trade contractors to identify risks and hazards and how they are to be managed on site. Methods of health and safety management will be constantly monitored and reviewed by the builder with consultation from Total Safe Services.

Public Safety. The builder will consider the health and safety of the public by taking necessary steps to ensure any activity on site does not cause members of the public any risk of illness or injury. When building in a built-up (eg area near occupied homes, schools, shops or playgrounds), the builder will implement measures to ensure the public cannot readily enter or access any part of the site where exposure to injury or illness may exist.

SITE SPECIFIC RULES

- All aspects of the WHS Act and Regulations 2011 will be strictly enforced; workers are reminded that they have a “due diligence” to ensure they comply fully with the Act and Regulations. A copy of the safety plan can be found in the electrical meter box on each site, workers must make themselves aware of its contents.

- Workers within 4 meters of operating plant and machinery must wear high vis clothing.

- No Alcohol or Drugs are allowed on site, workers suspected of been under the influence of these will be removed from site immediately.

- No children are allowed on site. No animals are allowed on site.

- All electrical equipment must meet the Australian Standard for Electrical on Construction sites.

- Housekeeping is an essential part of safety on site, all contractors must clean as they go, and failure to do so may incur a cleaning fee.

All food scraps, food containers and drink containers must be disposed of correctly, placed in the skip bin provided. - Theft of materials or equipment will be reported to the police immediately.

- No urinating on site, toilets are supplied please use them.

- Safety foot wear is compulsory on site at all times, workers not wearing the correct foot wear will be removed from site.

- All accidents and incidents must be reported immediately to your Supervisor or James Ferguson.

- Workers are reminded that public pathways are to be kept clear of vehicles and materials.

- All sub-contractors must supply and maintain a First Aid Kit for their workers; this kit must be always available and accessible.

ASCOT HOMES & GARAGES- SITE REQUIREMENTS – 2022

ASCOT HOMES & GARAGES promote a high degree of professional integrity to its clients and suppliers, to maintain a successful business, the client’s satisfaction is paramount, and therefore the following is required from all our sub-contractors and suppliers. We require each PRINCIPAL SUB-CONTRACTOR to enforce these requirements and ensure all staff always adheres to them .

1. Please always conduct yourself in a professional manner.

2. Only the stamped council approved plans are to be worked off.

3. All changes and rectifications must be approved by the office.

4. You must be issued with your written order before works can commence.

5. Any variations to orders must be authorised & raised before any works can commence.

6. Liaise with the office regularly.

7. Work with other contractors, to ensure the job progress quickly and efficiently always.

8. Before leaving the site ensure all windows and doors are closed.

9. Ensure the inside is sweep out and all rubbish placed into the skip bin. Do not just sweep it out the front and leave it.

10. All small off cuts, drink containers, food containers, food scraps must be placed in the bin.

1. All aspects of the WHS Act and Regulations 2011 will be strictly enforced.

2. All persons onsite will be competent in their job descriptions.

3. Each site has a construction safety plan located in the meter box which may be access at any time.

4. Please make housekeeping a high priority on all sites and ensure all excess building materials, food scraps and drink containers are deposited into the skip bins provided at the end of each day.

5. A Safe Work Method Statement will be required from subcontractors carrying out any high-risk activity, please ensure that all our employees and contractors conform to its requirements.

6. You must provide and maintain a suitable First Aid Kit, which will be available on each site.

7. Ascot Homes & Garages will be advised of any reportable accident or incident within 24 hours.

8. You will ensure all plant, machinery, tools and ladders, etc are correct for each task and when required meet the Australian Standard for Construction sites.

9. When workers are working at heights they will be experienced and competent in their tasks, all high-risk activities will have a SWMS, our employees and contractors will strictly adhere to.

10. Workers are aware of the importance of correct manual handling procedures and will endeavour to put these into practice on all sites.

11. Please ensure adequate supervision for all employees and contractors.

12. All employees and contractors will treat each person with respect, instances of bullying, harassment or physical violence will not be tolerated.

13. All electrical tools testing and tagging must be up to date

14. Do not operate any plant unless authorised to do so

15. Ensure the appropriate footwear – safety footwear to be worn which is relevant to the job description.

16. Ensure the correct protective clothing is always being worn

17. Persons affected by drugs and or alcohol are not permitted on the site.

The wearing of Thongs onsite at any time is Prohibited

|

EMERGENCY CONTACT NUMBERS |

||

|

Service |

Phone |

|

|

Ambulance |

000 for emergency 131233 for non-emergencies |

|

|

Fire Brigade |

000 for emergency 41507999 for non-emergencies |

|

|

Police |

000 for emergency 41539111 for non-emergencies |

|

|

Bundaberg Hospital |

41521222 |

|

|

Poisons Information Centre |

131126 |

|

|

Workplace Health and Safety Office |

41519724 |

|

|

Safety Consultant- Darryl Rasmussen |

0428 592 687 |

|

|

EMERGENCY PLAN AND CONTACTS |

||

|

Emergency |

Procedure |

|

|

Fire

|

If fire is discovered:

|

|

|

Ambulance

|

If an accident occurs:

|

|

|

Electrical |

If an electrical accident occurs:

|

|

|

Poison |

If poisoning occurs:

|

|

Reference: Workcover Code of Practice – Amenities for Construction Work

Safety Issue – Amenities

Method of Control

Toilets: The builder will ensure Toilet facilities are made available for workers and trade contractors.

Water: Where reticulated water is available it will be made accessible for workers and trade contractors within 30m. Otherwise potable water should be taken to site.

Meal room: The building under construction may be used for meals. Until the building reaches a stage where it provides shelter, contractors are to make their own arrangements.

Maintenance of Amenities: The builder will ensure all amenities provided are maintained in a clean, tidy, and serviceable condition. They will be kept free of accumulated or deposited materials, obstructions, or hazards that may affect a person’s health or safety

Safety Issue – Site Security

Method of Control

Where a perimeter fence is not used, before leaving the site unattended at any time, sub-contractors are to ensure that any hazards associated with their work are to be effectively secured from the effects of weather or intervention by unauthorised visitors. Barricading is to be considered when the construction site is next to schools, public places, high volume of pedestrian traffic. Where a perimeter fence is used, hazards associated with their work are to be similarly secured as well as all site access points. Access ladders are to be locked away or taken off site.

Sub-contractors’ are to ensure nothing is stored or placed outside the site boundary or fence unless the builder has approved such storage in writing.

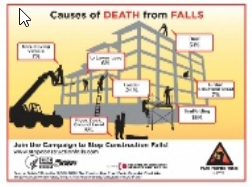

Safety Issue – Fall Protection

Method of Control

Where a fall height of 3 m or more is possible such as at change of levels, balconies, first floor stair voids or the like, a suitable barricade in the form of handrail, balustrade or similar, will be erected. Sub-contractors are to preserve the integrity of the barricade and ensure that all gates and access points are secured before leaving the site unattended.

Risk to other persons

Method of Control

Sub-contractors are to ensure that adequate precautions are in place to avoid any risk of injury or illness to other trades on site or members of the public.

Reference: Queensland WHS Regs 2011

Safe Work Method Statements (SWMS)

Method of Control

Sub-contractors are to provide a SWMS for the following activities-

a. Work involving structural alterations that require structural support.

b. Work at a height above two meters.

c. Work involving excavation to a depth greater than 1.5 meters.

d. Demolition work for which a demolition license is not required.

e. Work near traffic or involving the movement of powered mobile plant.

f. Work in or around gas or electrical installations.

g. Using a confined space.

h. Using a hazardous substance

i. Dust

Procedures outlined in the SWMS must be followed. Any departure can only be made after consultation and agreement with the principal contractor and all personnel involved with the activity.

Competency

Sub-contractors are to ensure that where licenses and certificates of competency are required to perform work, any employees or trade contractors they may use, will have proof of those qualifications or competencies. Any people employed or other contractors engaged are to be sufficiently trained and skilled to perform the work in a healthy and safe manner.

Safety Issue – Warning Signs

Method of Control

When working where hazardous situations occur such as in locations where there is a risk of being struck by falling objects, sub-contractors are to display appropriate warning signs. Warning signs are to be displayed so that they are clearly visible to any persons who are approaching the area in which the hazardous situation exists. E.g.: Danger Construction site do not enter

Safety Issue – Emergency and First Aid

Method of Control

Sub-contractors are to ensure that they have adequate first aid equipment in their vehicle. This first aid kit will be adequate for the type of injuries that could occur while performing their work. Sub-contractors must instruct all team members in emergency procedures applicable to each site. Emergency contacts are listed at the front of this Plan. First Aid Kits must be to the Australian Standard 2004 for Construction Sites.

A first aid report form can be located in the back of this safety plan, any incident which requires first aid treatment must be recorded and provided to the builder.

Safety Issue – Rubbish and Waste

Method of Control

Safety Issue -Materials

Method of Control

Where sub-contractors materials and equipment are to be delivered and stored on site arrangements are to be made with the principal contractor to ensure they are stored on site in a manner that is secure and does not cause injury or illness. More specifically, lightweight materials are to be secured so they are not blown over or away, and that fragile materials are stored and moved so they do not create additional hazards.

Safety Issue – Personal Protective Equipment (PPE)

Method of Control

Appropriate items of PPE are to be used where it is not practical to control risk of injury or illness by other means. Further to this, hard hats are to be worn when there is a risk of injury to the head, for example when working underneath other trades. Appropriate protective footwear is to be worn at all times. When selecting footwear, particular attention is to be given to the suitability for the activity being undertaken.

Safety Issue – Stability

Method of Control

While the structure is being built, sub-contractors are to ensure that their work is secured as necessary and does not adversely affect its stability. They are to ensure that the structure remains stable and secure from a collapse, which may be caused by: weather, wind, subsidence, construction loads, live loads, or the premature removal of temporary bracing or temporary propping.

Safety Issue – Protrusions

Method of Control

Where they are a hazard, sub-contractors are to ensure that sharp objects such as protruding tie-down bolts; reinforcing rods and mesh; bars; steel, copper and plastic tubing, metal flashing, wall ties etc. are removed, bent over or covered to eliminate or reduce risk of injury

Safety Issue – Ultra violet light

Method of Control

Sub-contractors are to ensure that their team members wear adequate clothing, and use methods such as hats and sunscreen, as protection from the effects of working in the sun.

Safety Issue – Light

Method of Control

Where work is to be undertaken in areas where insufficient light may cause injury sub-contractors are to arrange additional lighting

Reference: Workcover Code of Practice – Electrical practices for construction work.. (Electrical COP)

Safety Issue – Electrical.

Method of Control

Where our sites are provided with a 240 volt power supply it will comply with the wiring rules and electrical COP, including protection by a Residual Current Device (RCD). Where sub-contractors are distributing power to several tools the distribution board must have its own RCD. Where sub-contractors provide their own generator it must be fitted with its own, hardwired RCD. Hire units should be checked to ensure they comply

Sub-contractors are to maintain compliance with the applicable standards and electrical COP and make sure that:

- All extension leads, portable tools and electrical equipment operating above 32 volts are tested and tagged as required by the electrical COP

- Portable electrical equipment will be of an industrial standard.

- Power leads are located so as not to create a hazard and to minimise the risk of damage. They are to be kept away from water, checked daily for damage and repaired as required.

Extra protection for or relocation of power leads is to be provided as required in areas of high traffic.

In all cases relating to electrical, the AS/NS 3012:2003 will be adhered to:

- All tools and Leads must be checked and tagged every 3 months.

- Meter box doors must be kept shut, with leads up through the bottom.

- Leads must be tied to the tie bar.

- Double adaptors and power boards are illegal on a construction site.

- Check lead lengths for voltage drop.

- R.C.D must be checked every day.

If working near live parts- minimum safe distances are:

-

- One metre clear of house supply from pole in street to building or structure connection (240-415v)

- Three metres clear of power lines in the street.

Nine meters clear of high voltage power lines on poles or towers.

Reference: Workcover safety guide No 4503 – Portable Ladders

Ladders used on our sites are to be of an industrial standard complying with AS 1892 – Portable ladders, with a minimum load rating of 120 kg. Guidelines outlined in WorkCover Safety guide No 4503 – Portable Ladders are to be followed and sub-contractors are to ensure that:

- Ladders are secured, where necessary, to prevent movement during use.

- Precautions are taken for the base stability of ladders, particularly on soft or uneven soils.

- Ladders are maintained in a sound working condition.

- Ladders will be secured at the top as a minimum.

- Ladders are not to be used as a working platform.

- Extend at least 1 meter above the surface.

- Not be used to support a platform (e.g. Planks)

Ladder are industrial standard.

Reference: AS 6001 – Working platforms for housing construction

Working Platforms on Trestle Systems

Trestle systems used on our sites must be erected in accordance with manufacturer or supplier’s instructions, and good practice, as outlined in AS 6001. Sub-contractors must ensure that:

- Platforms are erected as near as reasonable to level, and are stepped rather than sloped.

- Platforms and trestle systems are kept in good and sound condition.

- When working over 3metres the gap between the planks and working surface must be less than 225mm.

- Trestle must be braced to the wall or by bracing poles.

- The platform must be unobstructed along its length and no higher than five meters.

Trestles are placed on a firm surface or sole plates, to maximize stability.

Reference: AS 1576 – Scaffolding; AS 4576 – Guidelines for scaffolding

Safety Issue -Working Platforms on Scaffolds

Method of Control

When sub-contractors use or supply scaffolding it must be erected and/or used in accordance with the manufacturer or supplier’s instructions, and good practice, as outlined in AS 1576 or AS 4576. When scaffolding is to be loaded with materials, the scaffolding will be capable of supporting the applicable loading, heavy, medium or light duty as outlined in Australian Standard 1576.

Scaffolding must be erected as near as reasonable to level and be fully decked when in use.

Any scaffold must be erected in accordance with:

- A scaffold plan-copy to be provided to the principal contractor.

- The provisions of the QUEENSLAND WPHS Act / Regulations and the Scaffolding Advisory Standard.

- Any person erecting scaffolding where a person or object could fall four metres or more must be a ticketed scaffolder and hold the certificate of competency. The builder will record these details.

- The person responsible for the erection of any scaffold over 4 metres in height must provide the builder with a “hand over” certificate; this will be kept on site, with a Scaftag completed an attached at the stairs.

- Any person performing scaffold work on site, regardless of height, must be competent to do so.

While erecting, altering or dismantling the scaffolding, the subcontractor must:

- Install it systematically to manufactures specification, including all braces, ties etc.

- Ensure each hazard that a person may fall into (bricks, reinforcing steel or material/rubbish) is identified, assessed and controlled.

- Use a platform at least 450mm wide along the full length of the section to erect components to the level above.

- Install edge protection as soon as each section has enough components in place to allow it.

- Provide a means of safe access to the level the scaffolding has reached, before the next level of scaffolding is erected.

To dismantle a scaffold, use the above steps in the reverse order.

Tools, Plant and equipment

Sub-contractors’ tools and equipment used on our sites are to be checked on a daily basis to ensure that where appropriate the guards are fitted and working effectively.

All sub-contractors should keep a register of all their plant on site and if any plant or equipment is damaged, it must be removed from service and tagged “out of service” or similar. Drop saws to be set up at waist height, before use.

All equipment must be in good condition, be serviced and maintained as per the manufactures’ requirements.

Reference: Workcover Code of Practice – Manual Handling

Manual Handling

Sub-contractors are to ensure that their team members are aware of and follow good manual handling techniques and risk assessment procedures as outlined in the Code of Practice. When lifting awkward and heavy items, we will endeavour to use mechanical aids. Where this is not practical we will consider team lifting.

- Use mechanical aids where possible

- Ensure your back is in the upright position.

- Use your legs to do the lifting not your back

- Keep work areas tidy to avoid tripping hazards.

Reference: Workcover Code of practice – Excavation

Trenching and Excavation

When creating or working in trenches or excavations on our sites, the subcontractor responsible must ensure that an adequate system of safety is in place, involving as appropriate, shoring, earth retention equipment or other measures to control risks to health and safety arising from one or more of the following:

a. the fall or dislodgement of earth, rock or other material from a height of more than 1.5 meters or

b. the instability of the excavation or any adjoining structure or

c. the inrush of water or

d. the placement of excavated material or

e. instability due to persons or plant working adjacent to the excavation or

f. Unplanned contact with electricity cables, gas mains or other utility services.

g. All excavations should be clearly marked with a barrier.

As required by OHS Regulation 2001, when working in excavations subcontractors must ensure that:

for excavations with a depth of 1 metre or more, a competent person inspects the work at intervals determined by a risk assessment having regard to the particular work and nature of the material being excavated and for excavations with a depth greater than 1.5 metres subcontractors must provide the principal contractor with a Safe Work Method Statement for the activity and safe means of access and egress to and from trenches or excavations is provided.

Reference: WorkCover Safety Guide – Safe movement of plant on construction sites

Work near Mobile Plant

OHS Regulation 2001 classifies construction work near mobile plant, such as concrete pumps and excavating machinery, as “High risk construction work”. As required by the Regulation, we will provide the principal contractor with a Safe Work Method Statement for those activities.

Controls for the Safe Operation of Plant

The use of specific measures to eliminate or minimize identified risks should involve the selection of the most effective control measures based on a risk assessment. The following are some of the control measures that should be considered:

- Isolating vehicles and plant from persons on site

- Using fencing, barriers, barricades, temporary warning or control signs

- Planning the direction that plant moves, so visibility is not restricted

- Implementing safe working distances using clear communication systems

- Minimizing amount of plant working at one time

- Using demarcation lines or zones

- Using audible reversing alarms

- Using reversing sensors

- Using reversing cameras

- Using flashing lights

- Using high visibility garments

- Using spotters or observers.

Safe work methods and vehicles movement procedures are required under the WPHS Act and will assist in ensuring the safety of workers and the public around moving plant.

Workers should be consulted during the development of the WMS and the vehicle movement procedures, and receive instruction on the procedures.

All operators of mobile plant will be trained in Safe Operating Procedures of the mobile plant.

Activities of other plant, cranes and machines

Sub-contractors must follow the safety instructions of drivers or licensed operators of plant. They are to maintain an awareness of and a safe distance from such activities.

All mobile Plant and Machinery must supply a Safe Work Method Statement before work commences.

Because cranes and mechanical lifting gear are used to handle excessively heavy loads, there is always potential for injury to the operator and others.

Before the operation begins the builder or his representative will assess the equipment, its location, setting up and intended use.

The builder or his representative will ensure:

- The crane and equipment is adequate for the job

- The crane operator has appropriate Certificate.

- Doggers and Riggers have appropriate Certificate.

- The crane components are properly maintained.

- Persons will not be struck by the crane.

Hazards to be aware of are:

- Walkways, power lines

- Trenches, pits

- Unstable surfaces, steep gradients

- Projecting objects and other vehicles.

Where necessary the builder or his representative, will supply a competent person as a “spotter” for the operator.

Confined Spaces

The supervisor shall examine the confined spaces that exist at the worksite and, as necessary, develop detailed instructions for safe entry and working therein using these instructions as guidelines.

Definitions:

Confined spaces are any space:

- From which there is no ready and/or safe escape for a person if they become inadvertently locked inside, or if a dangerous situation develops while a person is inside; and/or

- Which contains or has contained an harmful substance or any harmful fumes or substances capable of producing these fumes; or

- Which contains, has contained, is made of, lined or coated with any substance or substances capable of causing the amount of oxygen to be reduced to a dangerous extent.

Conditions of Entry or Re-entry:

Before Entry, or Re-Entry into a confined space, the Supervisor must assess the situation and determine which hazards exist and/or could exist. These could include one of the following:

- Explosion and/or fire hazard

- Extreme temperature (hot or cold)

- Insufficient air for breathing

- Electric Shock

- Insufficient lighting

- Obstructions

- Noise

- Dust

Action List:

- Isolate the space from all sources, which can supply harmful substances or fumes.

- Make regular checks to ensure that the atmosphere remains safe and ensure that workers entering the confined space are appropriately trained for the task.

- Whenever possible, provide more than one means of exit or escape so that an alternative escape route is available in the event of danger arising.

- Ensure that workers concerned shall be instructed in the emergency procedures, which should be observed in the particular situation.

- Arrange for the provision of Protective Equipment as appropriate.

- Wear Dust masks.

- Wear Eye protection.

- Wear appropriate clothing.

- Provide adequate lighting in confined spaces.

- Brief all staff and subcontractors at the beginning of work, making them aware of all the safety issues.

Obtain management support to provide a safe working environment

Queensland WHS Code of Practice for “Crystalline Silica Dust”

Silica Dust

Drilling, cutting, breaking and grinding of concrete the following controls are to be used:

- Vacuum rather than sweeping, vacuum must be a HEPA with an M OR H class filter (disposable bags are preferred)

- Water suppression – when using water as a control, consider wearing a P2 Mask when required.

- Vacuum dust collection systems, . Ventilation

- As a minimum a P2 Face mask which has been FIT TESTED must be Used for all dry work when cutting, drilling, breaking, grinding concrete.

- Workers to under take health monitoring on 30 days or more in a 12 month period – this means that worker who puts on a mask to do any task must receive health monitoring.

Subcontractors have the following environmental responsibilities:

- Maintain silt fence- alise with builder on position.

- Sweep up spilt materials on a road, footpath, and gutter as soon as possible during operations, inclement weather or before leaving job site.

- Keep dirt etc out of gravelled areas.

- Do not track dirt onto road.

- Temporary down pipes to be maintained

- Ensure water from brick cutters etc is not entering gutters.

- Dust must be contained

All excess paints, washing of painting tools must not enter the gutters

|

HAZARDOUS SUBSTANCES |

|

SAFETY DATA SHEETS ARE TO BE KEPT AND MAINTAIN BY THE RELEVANT PERSONS SUPPLYING AND USING CHEMICALS ON SITE. |

|

In all cases of poisoning contact the Poisons Hotline……………. 13 11 26 |

If using a hazardous substance on the site, the subcontractor has the following obligations:

Obtain the hazardous substance’s Safety Data Sheet – suppliers must legally supply SDS ON request.

Perform a risk assessment on the use of the hazardous substance and keep a record.

Train any persons who will be using the hazardous substance in its safe use.

Keep a register containing a list of all hazardous substances.

Advise the builder that they propose to use the hazardous substances on site.

Prepare a Work Method Statement for the use of the hazardous substances and provide this to the builder before starting work.

|

Register of Documentation Forms |

|

No |

Form |

Page |

|

1 |

Existing Services |

|

|

2 |

Site Inspection Checklist |

|

|

3 |

Accident/Incident Report Form |

|

|

4 |

Tool Box Talk |

|

|

5 |

|

|

|

6 |

RISK ASSESMENT – PLANT/TASK/ACTIVITY |

|

|

7 |

Environmental Information |

|

EXISTING SERVICES PROJECT:

Ascot Homes & Garages has identified the following underground and overhead services located at the site. Below are the details of each including location, depth, and height?

Underground Services

|

Electrical cables: |

|

|

|

Storm water pipes or services: |

|

|

|

Gas pipelines: |

|

|

|

Fuel tanks or pipes: |

|

|

|

Water pipes: |

|

|

|

Sewerage pipelines or services: |

|

|

|

Telephone and computer cables: |

|

|

|

Other servcies(specify) |

|

|

Overhead Services

|

Electrical cables: |

|

Telephone / Computer cables: |

|

Television: |

|

Other services(specify) |

SITE INSPECTION CHECKLIST

PROJECT:

INSPECTING PERSON: DATE:

|

Rating Column |

|

Acceptable |

NA |

Not Applicable |

R |

Rectified during inspection |

||

|

|

Rectification within 24 hrs required |

S |

Instruction Issued to Personnel |

|||||

|

ITEM |

RATING |

ITEM |

RATING |

|||

|

1. Previous Inspection Items Appropriately Actioned |

|

18. All Underground Service Checks Done & Communicated to Subcontractors |

|

|||

|

2. All Subcontractors’ Details Contained Within the Subcontractor Register |

|

19. Safe Trenching & Excavation Practices to Avoid Collapse |

|

|||

|

3. All Relevant Subcontractor Work Method Statements Reviewed and Approved |

|

20.0 Sign-off Received from Scaffolder in Relation to Scaffold Completion |

|

|||

|

4. General Safety Induction Evidence Sighted for All On-Site Personnel |

|

21. Scaffold Remains in Safe Condition with Adequate Edge Protection |

|

|||

|

5. Emergency & Evacuation Info Correct and Prominently Displayed |

|

22. Scaffolding Fitted with Adequate Brick Guards and Access Provisions |

|

|||

|

6. Hazardous Substances Register Complete & as per On-Site Substances |

|

23. Switchboard in Good Condition with Leads Appropriately Connected |

|

|||

|

7. MSDS contained with Hazardous Substances Register |

|

24. Residual Current Device Checked and Operational |

|

|||

|

8. Site Signage Displayed Prominently and Safely |

|

25.0 Safe Portable Power Tool Practices |

|

|||

|

9. Amenities Provided and Well Maintained |

|

26. Adequate Guarding of Tools and Equipment |

|

|||

|

10. Access Ways are Clear of Tripping Hazards |

|

27. Safe Hazardous Substance Use, Storage and Clean Up |

|

|||

|

11. Rubbish Skip is Appropriately Positioned and being Regularly Emptied |

|

28. Safe Work at Height Practices During All Tasks On-Site |

|

|||

|

12. Boundary Fence Remains in Place and is Stable in all Sections |

|

29. Controls in place to minimise the risk of Objects Falling from Heights |

|

|||

|

13. Access to the Site is being Adequately Excluded/Controlled |

|

30. Safe Subcontractor Work Practices as per Work Method Statements |

|

|||

|

14. Parking & Delivery Vehicles Practices are being done Safely & with Spotters |

|

Other Specific Requirements Identified by Site Supervisor during the Site Inspection |

|

|||

|

15. Mandatory PPE being worn |

|

31.

|

|

|||

|

16. Activity Specific PPE being worn as per Subcontractor Work Method Statements |

|

32.

|

|

|||

|

17. Prescribed Occupation holders only are Undertaking Prescribed Work Activities |

|

33. |

|

|||

|

Comments: (Provide brief Description & Location of the OHS Issued Identified Above) |

||||||

|

|

|

|

|

|||

|

|

|

|

|

|||

|

|

|

|

|

|||

|

FOLLOW UP ON PREVIOUS INSPECTIONS |

||||||

|

Date |

Item No. |

Result |

Further Action |

|||

|

|

|

|

|

|||

|

|

|

|

|

|||

|

|

|

|

|

|||

|

|

|

|

|

|||

INSPECTING PERSON:……………………………………… DATE:……………………………….

Incident Report Form – Sub-Contractor Employee

(to be completed for all workplaces)